Filipino researchers are using artificial intelligence (AI) and 3D printing technologies to enhance bone tissue repair, providing a more accessible and affordable solution for bone-related challenges caused by aging, infections, and accidents.

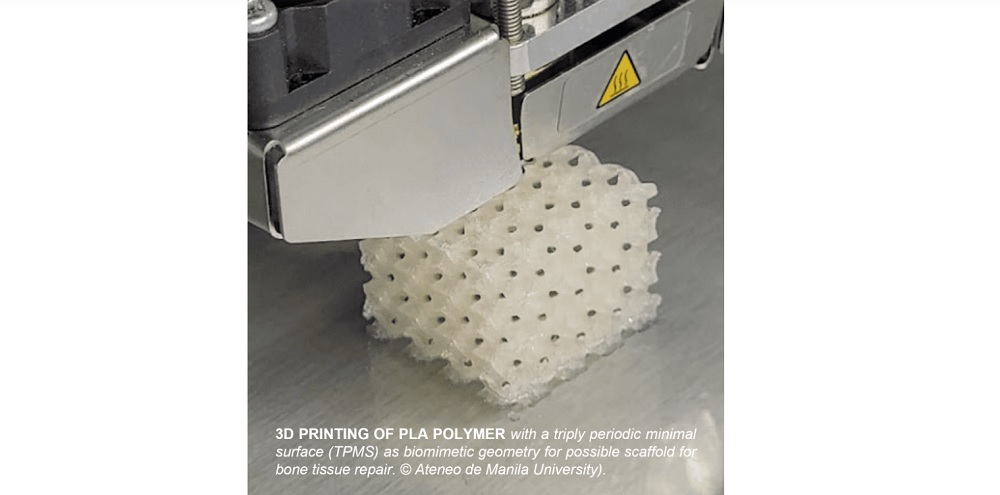

Aiming to empower patients and doctors in selecting the optimal bone repair material based on medical needs and affordability, the project offers a more viable alternative to existing methods by providing enhanced performance for complex bone regeneration using 3D printing technology to craft bone scaffolds with tunable shapes.

Led by Dr. Erwin P. Enriquez of the Ateneo de Manila University (AdMU), and supported by the Philippine Council for Health Research and Development (PCHRD), the team leverages on an international collaboration with researchers from the Vellore Institute of Technology in India, that specializes in additive manufacturing, AI-assisted design, and bio-nanotechnology using 3D printing technology.

In its second year, the project has developed a machine-learning model to analyze factors affecting the effectiveness of bioceramic precursor materials in printing.

Simultaneously, the team explores polymer-nano clay materials and 3D-printed frameworks, ensuring strength and compatibility with the human body.

“By integrating transformative technologies like AI and 3D printing, we are charting a course towards a future where healthcare is revolutionized, and innovative approaches become the cornerstone of medical advancements. This collaborative initiative, showcasing the dedication and expertise of our team, holds promise in providing accessible and affordable solutions for bone-related challenges,” stated Dr. Jaime C. Montoya, PCHRD executive director.

Recognizing the limitations of traditional transplantation, the researchers advocate for a shift towards regeneration as a more promising solution for damaged tissues and organs.

The project, set to conclude in August 2024, focuses on refining additive manufacturing and processing techniques, aiming to significantly reduce fabrication time compared to current technologies.

Once successful, the initiative may empower surgeons with a diverse selection of composite materials, custom-tailored to meet the medical and financial needs of individual patients.